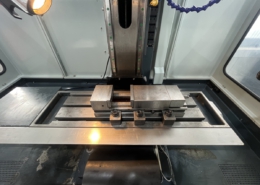

OPTIMUM – M4HS CNC

Machine comes from a university and was used sporadically.

including vice

including electric Handwheel

including work light

including coolant pump

including machine feet

including central lubrication

Stable CNC milling machines with professional Siemens 802 S baseline control,

ideal for users in mold making

Ball screw spindle from HIWIN in all axes

Solid, precise cross table, large dimensions and precisely surface-machined.

Heavy, solid cast design

Adjustable wedge strips

Very wide speed range Continuously variable drive

Electronic handwheel reduces setup time to a minimum

Compact housing design Foldable housing side parts for easy access to the

machine

The work area is clearly visible from three sides thanks to clear Macrolon panes

Base is designed on two sides. Front with access to the coolant tank Rear with

access to the electronics and the Optimum CNC controller IV

Siemens Micromaster as a frequency converter

All doors with safety switches

ER32: for high speed and normal machining

Linear guide in the Z axis

Central lubrication